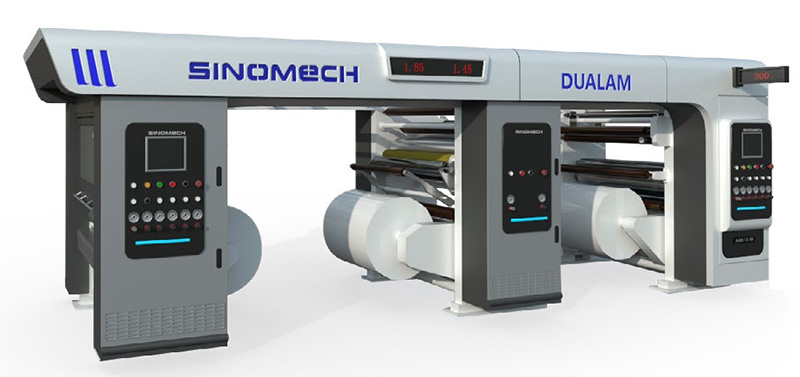

Dualam Solventless Laminating Machine

Solventless Lamination Machine

This solventless laminating system features dual coating units and was developed through a collaboration that combines over 17 years of lamination engineering experience with more than three decades of adhesive formulation expertise. Launched in 2023, our laminating equipment offers precise control, stable performance, and enhanced flexibility for multi-layer flexible packaging.

- Max laminating speed: 300m/min

-

Max web width: 1050/1300mm

-

Max unwinding diameter: 800mm

-

Max rewinding diameter: 1000mm

-

Inner diameter of core: 3'' or 6''

The solventless laminating machine is equipped with two independent coating units: a five-roller transfer coating system and a closed-chamber gravure unit. A- and B-component adhesives are applied separately to each substrate before lamination and rewinding. Compared to conventional solventless laminating systems, this dual-coating approach offers several significant advantages:

- No mixing unit is required, eliminating the risks associated with improper mixer cleaning or maintenance

- Curing time is significantly reduced, laminates can move on to slitting or pouch conversion in as little as six hours, helping shorten delivery timelines

- The adhesive's long open time allows for easier job changeovers without needing to clean the coating units between runs

- Fewer bubbles are produced during the adhesive reaction, resulting in improved visual quality, especially important for high-barrier film structures

- Supports curing at room temperature (20–25°C), reducing both energy consumption and carbon emissions

Get in Touch

As a leading solventless lamination machine manufacturer in China, SINOMECH offers various solventless laminators in standard and customized models to meet different lamination needs in the fields of flexible packaging, tobacco packaging, home decorative materials, etc. Whether you are manufacturing laminates to pack food, goods or liquids, SINOMECH lamination machines with high performance are the perfect choice for your products. As important converting machinery, our web lamination machinery is designed to meet the highest quality and product safety requirements. Various substrates including plastic film, metalized film, alu foil, rigid film, paper, cardboard adapt to being laminated with our machines. In addition to the film laminators, we also provide flexo printing press and slitting machine to realize one-stop solution for manufacturing your packaging. Thanks to our own research and development, we are able to find the perfect lamination solution for each product without forgetting environmentally friendly solutions. We are always ready to help you with our know-know in the laminating industry.

-

- Standard Adhesive Mixer, SM1-40

- Mixing ratio

- 30:100~100:100

- Gear pump driver motor

- servo motors

- Tank capacity

- 2 x 40L

-

- Solventless Laminator (for Cheese Stick Packaging)

- Max lamination speed

- 150m/min

- Max web width

- 1300/1500mm

- Max unwinding diameter

- 800/1000mm

-

- Solventless Laminator (for Decorative Materials)

- Max lamination speed

- 50m/min

- Max web width

- 1300/1500mm

- Max unwinding diameter

- 600mm

-

- BOOMING Gearless CI Flexo Printing Press

- Print width

- 1200mm

- Print unit

- 8 colors

- Printing repeat length

- 380 ~ 880 mm